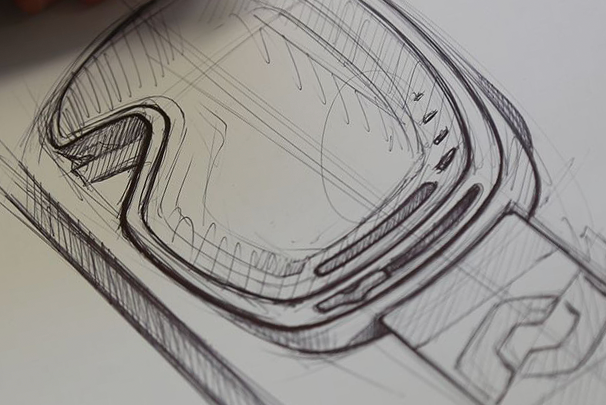

1Pre-Production

During this stage, Fetop designs and develops molds for components and products (goggles) in accordance with the agreed schedule. Our team of experts has an eye for detail, we will show you pre-press results, make mock-ups , and do proof design until you are sure you are satisfied with the result.

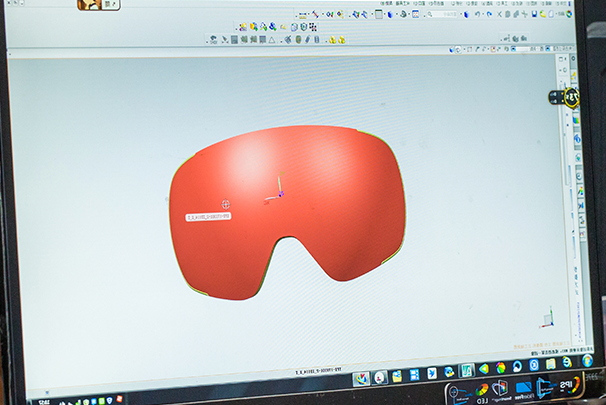

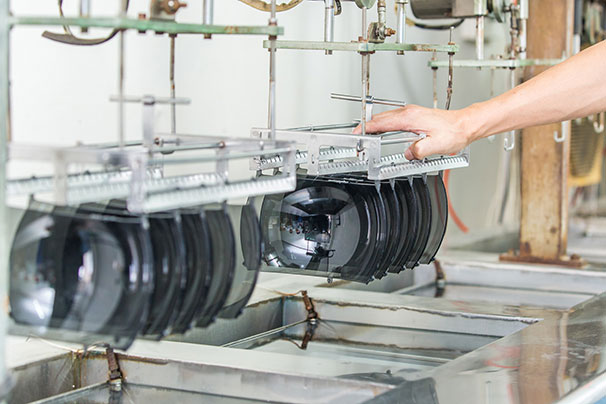

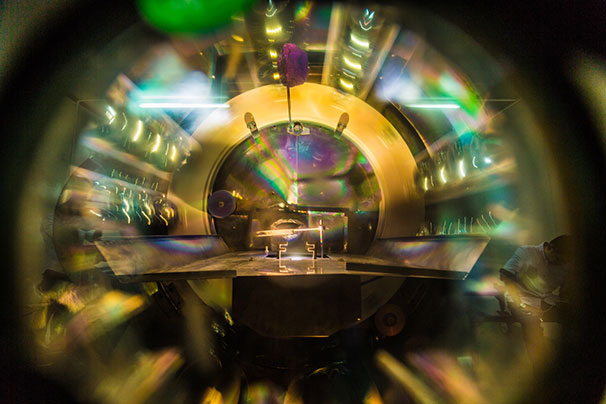

2Lens Production

Fetop Precision Optics is a quality label which stands for premium materials and innovative manufacturing techniques.

We are the one and only company in the industry to have various types of lens materials (PC lens, Photochromic, Polarized, Photochromic-polarizing lens and Prizm lens) and the technologies (HC, AF, AR Coating) for production.

3Frame Production

This is the first processing procedure for goggle frames, which is one of the three parts of the product (goggle). During this process, frames are made with the raw material on a mold that is loaded on the injection-molding equipment.

4Strap Production

Last but not least, the strap. Besides being important aesthetically, it requires the same durability as the lens and frame while providing stability around your head.

5Assembling and Quality Control

This is the last step of the product processing procedure. In this process, three aforementioned parts (lens/frame/strap) are assembled and the finished products are packaged together with a manual and various packaging materials.